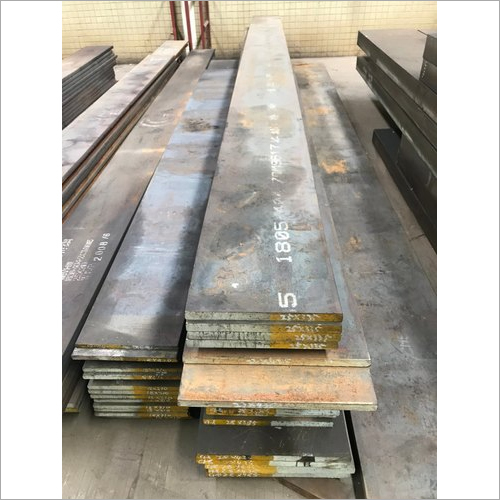

H13 Hot Die Steel

Price 270 INR/ Kilograms

H13 Hot Die Steel Specification

- Product Name

- Steel

- Steel Type

- Hot Die Steel

- Steel Product Type

- Steel Bars

- Grade

- H13

- Thickness

- 25 Millimeter (mm)

- Application

- Used in hot and cold work tooling applications

- Color

- Grey

H13 Hot Die Steel Trade Information

- Minimum Order Quantity

- 5 Kilograms

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- Days

- Main Domestic Market

- All India

About H13 Hot Die Steel

With almost years of experience, we have been able to supplier quality assured H13 Hot Die Steel. The offered bar is manufactured with precision by our dexterous troop of professionals at our premises using quality tested mild steel and contemporary techniques. The provided bar finds its wide usage in fabrication and construction work. Our reputed patrons can get this H13 Hot Die Steel from us in varied dimensions at marginal rates.

Specification

|

Material Grade |

H13 |

|

Single Piece Length |

10 ft |

|

Usage/Application |

Used in hot and cold work tooling applications |

|

Shape |

Flat |

|

Technique |

Hot Rolled |

|

Thickness |

25 mm |

|

Rust Proof |

Yes |

|

Hardness |

38 to 48 HRC |

|

Temperature |

1100 Degrees Fahrenheit |

Versatility in Tooling Applications

H13 Hot Die Steel bars serve a dual role in both hot and cold work operations, making them versatile across different sectors. Their robust build and high thermal stability allow them to withstand substantial temperature variations, ensuring consistent results whether used in forging dies or cold punches. Their adaptability makes them an essential choice for toolmakers and engineers.

Distinctive Properties for Industrial Strength

Renowned for their high-grade alloy composition, H13 Hot Die Steel bars resist cracking even under rapid heating and cooling cycles. The products 25 mm thickness offers structural strength, while its grey hue indicates a refined alloy mixture. These characteristics contribute to long-lasting performance and reduced maintenance overheads in tooling setups.

FAQs of H13 Hot Die Steel:

Q: How is H13 Hot Die Steel manufactured for tooling applications?

A: H13 Hot Die Steel bars are produced through a combination of alloying, melting, forging, and precise heat treatments. This process enhances their hardness and ensures excellent resistance to thermal fatigue, making the bars suitable for both hot and cold work tooling.Q: What are the main benefits of using H13 Hot Die Steel bars in industrial environments?

A: The primary advantages include superior toughness, high resistance to wear and heat, and the ability to maintain strength at elevated temperatures. These qualities extend tool lifespan, minimize downtime, and support consistent performance during intensive manufacturing processes.Q: When should H13 Hot Die Steel bars be chosen over other steel types?

A: H13 bars are ideal when tooling must endure frequent temperature fluctuations and mechanical stress, such as in forging, extrusion, or die casting. They are a preferred choice whenever longevity and stability in hot or cold environments are required.Q: Where in India can you source H13 Hot Die Steel bars?

A: These steel bars can be sourced from a network of reputable suppliers, traders, and wholesalers throughout India, catering to the needs of industrial toolmakers and manufacturers nationwide.Q: What is the typical process for integrating H13 Hot Die Steel into tooling production?

A: Integration involves selecting the bar grade and thickness, machining to desired shapes or molds, followed by heat treatment for optimal properties. Consistent quality checks ensure the finished tooling meets industrial performance standards.Q: How does the specified thickness of 25 mm enhance the usage of H13 Hot Die Steel bars?

A: A 25 mm thickness provides additional durability, allowing the steel bars to withstand considerable stress and resist deformation. This makes them apt for applications where tool integrity is critical under heavy loads.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hot Die Steel Category

H11 Hot Die Steel

Price 210 INR / Kilograms

Minimum Order Quantity : 5 Kilograms

Grade : H11

Application : Other

Steel Product Type : Other

Color : Silver

|

SHREE BALAJI STEEL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry