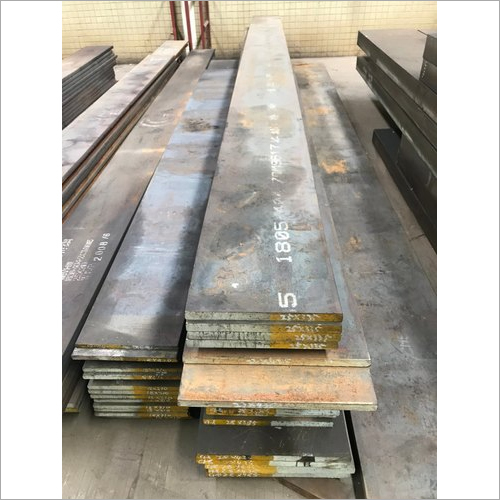

H11 Hot Die Steel

Price 210 INR/ Kilograms

H11 Hot Die Steel Specification

- Steel Type

- Other

- Steel Product Type

- Other

- Grade

- H11

- Application

- Other

- Dimension (L*W*H)

- 3 Meter (m)

- Color

- Silver

H11 Hot Die Steel Trade Information

- Minimum Order Quantity

- 5 Kilograms

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- Days

- Main Domestic Market

- All India

About H11 Hot Die Steel

Owing to our immense industrial experience and knowledge in our functional domain, we are catering optimum quality H11 Hot Die Steel. Our offered bars are used with electrical cables, but air and water hoses as well. These bars are manufactured by utilizing optimum quality stainless steel as per the instruction provided by our team of deft professionals. Available in different sizes and specifications, the H11 Hot Die Steel can be purchased from us at a marginal price range.

Specification

|

Usage/Application |

Used in hot and cold work tooling applications |

|

Shape |

Round |

|

Material Grade |

H11 |

|

Single Piece Length |

3 meter |

|

Technique |

Hot Rolled |

|

Hardness |

38 HRC |

|

Density |

7.80 g/cm3 |

|

Temperature |

1500 Degree Fahrenheit |

Exceptional Strength & Thermal Stability

H11 Hot Die Steel is valued for its outstanding toughness and resistance to high temperatures. This makes it the material of choice for demanding industrial tasks, such as hot forging and die casting. Its durability significantly reduces wear, ultimately increasing tool longevity and minimizing operational downtime.

Precision Dimensions for Versatile Applications

Measuring 3 meters in length, H11 Hot Die Steel provides flexibility in application for toolmakers and engineers. Whether used for moulds, dies, or precision parts, its standard sizing ensures easy handling and adapts well to various custom manufacturing requirements.

FAQs of H11 Hot Die Steel:

Q: How is H11 Hot Die Steel typically used in industrial applications?

A: H11 Hot Die Steel is primarily used in the manufacture of hot dies, extrusion tools, and die casting molds due to its high thermal resistance, strength, and stability at elevated temperatures. It is also favored for tools where durability is critical.Q: What process is followed to ensure the quality of H11 Hot Die Steel?

A: H11 Hot Die Steel undergoes strict metallurgical processes, including precise alloying, heat treatment, and rigorous quality assessments, ensuring consistency in performance, toughness, and resistance to thermal fatigue.Q: When should H11 Hot Die Steel be chosen over other die steels?

A: Select H11 when your project demands frequent exposure to extreme heat, high mechanical stress, and excellent resistance to heat checking, particularly in applications like hot die forging and aerospace tooling.Q: Where can I procure H11 Hot Die Steel in India?

A: This steel grade is available through reputable suppliers, traders, and wholesalers across India. You can source it easily by contacting authorized dealers who specialize in industrial-grade steels.Q: What are the main benefits of using H11 Hot Die Steel?

A: The chief advantages include exceptional heat resistance, superior toughness, extended operational life, and reduced downtime in high-temperature environments, making it a cost-effective choice for industrial tooling.Q: How does the standard dimension of 3 meters enhance its industrial utility?

A: A 3-meter length provides versatility for manufacturers, allowing for fabrication of longer or multiple smaller components, minimizing material wastage during production.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Hot Die Steel Category

H13 Hot Die Steel

Price 270 INR / Kilograms

Minimum Order Quantity : 5 Kilograms

Product Name : Steel

Steel Product Type : Steel Bars

Application : Other, Used in hot and cold work tooling applications

Steel Type : Other, Hot Die Steel

|

SHREE BALAJI STEEL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry