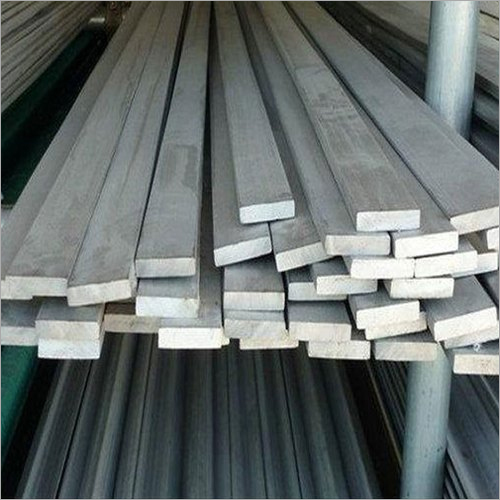

D2 Die Steel

Price 280 INR/ Kilograms

D2 Die Steel Specification

- Corrosion Resistant

- Yes

- Heat Resistance

- Yes

- Product Name

- Steel

- Grade

- D2

- Surface

- Polished

- Application

- Automobile Industry

- Dimension (L*W*H)

- 6 Meter (m)

- Color

- Grey

D2 Die Steel Trade Information

- Minimum Order Quantity

- 5 Kilograms

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 1000 Kilograms Per Day

- Delivery Time

- 7 Days

- Main Domestic Market

- All India

About D2 Die Steel

We are embraced as the experts as the renowned suppliers and traders D2 Die Steel from a vast number of years. In order to meet the varied needs and requirements of the customers, we diligently manufacture these flat bars in various specifications. Also, this D2 Die Steel is highly applied in the engineering, chemicals and food industries. Moreover, all these products are being offered at market competitive prices and in a timely manner.

Specification

|

Usage/Application |

Automobile Industry |

|

Shape |

Flat |

|

Material Grade |

D2 |

|

Hardness |

55 to 62 HRC |

|

Technique |

Cold Rolled |

|

Length |

6 m |

|

Temperature |

425 Degree Celsius |

Exceptional Wear Resistance

The D2 grade die steel is engineered to endure heavy-duty use, especially where abrasion is a constant challenge. Its high chromium content enables the steel to maintain its edge and structural integrity, significantly reducing the frequency of replacement or repairs in automotive manufacturing.

Precision and Versatility for Automotive Use

With dimensions of 6 meters and a robust composition, D2 Die Steel is well-suited for crafting intricate components in the automobile industry. It can be precisely shaped and machined, making it a go-to choice for dies and punches, essential for vehicle part production.

FAQs of D2 Die Steel:

Q: How is D2 Die Steel typically used in the automobile industry?

A: D2 Die Steel is primarily employed to manufacture dies, punches, and cutting tools required in the forming and stamping of automotive parts. Its excellent hardness and resistance to abrasion make it suitable for components that must withstand continuous stress and wear.Q: What benefits does D2 Die Steel offer compared to other tool steels?

A: The key benefits of D2 Die Steel include superior wear resistance, high dimensional stability, and the ability to hold a sharp edge for extended periods. These properties result in longer service life and reduced downtime in industrial applications.Q: When should D2 Die Steel be selected for a project?

A: D2 Die Steel is best chosen when applications demand hard-hitting, high-precision tools that function under abrasive conditions, such as those found in automobile manufacturing. If consistent quality and durability are priorities, D2 is an optimal solution.Q: Where can I purchase D2 Die Steel in India?

A: D2 Die Steel is widely available through reputed suppliers, traders, and wholesalers across India. These distributors offer the steel in various forms to meet the requirements of industrial clients, especially those in the automotive sector.Q: What is the process to prepare D2 Die Steel for use in component manufacturing?

A: The steel is first cut to the required size and then heat-treated to reach the desired hardness and toughness. After heat treatment, it undergoes precise machining and surface finishing to suit specific application needs.Q: How does the grey color and finish of D2 Die Steel relate to its application?

A: The grey coloration is characteristic of D2 Steels alloy composition and processing methods. It indicates a robust material suitable for demanding industrial tasks, such as automotive part fabrication, where reliability and performance are critical.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Die Steel Category

D3 Die Steel

Price 135 INR / Kilograms

Minimum Order Quantity : 5 Kilograms

Color : Grey

Grade : D3

Thickness : Available from 5 mm up to 250 mm Millimeter (mm)

Usage : Die making, Tool manufacturing, Industrial applications

HCHCR Die Steel

Price 135 INR / Kilograms

Minimum Order Quantity : 5 Kilograms

Color : Grey

Grade : HCHCR

Thickness : 20 Millimeter (mm)

Usage : Industrial

|

SHREE BALAJI STEEL

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry